- …

- …

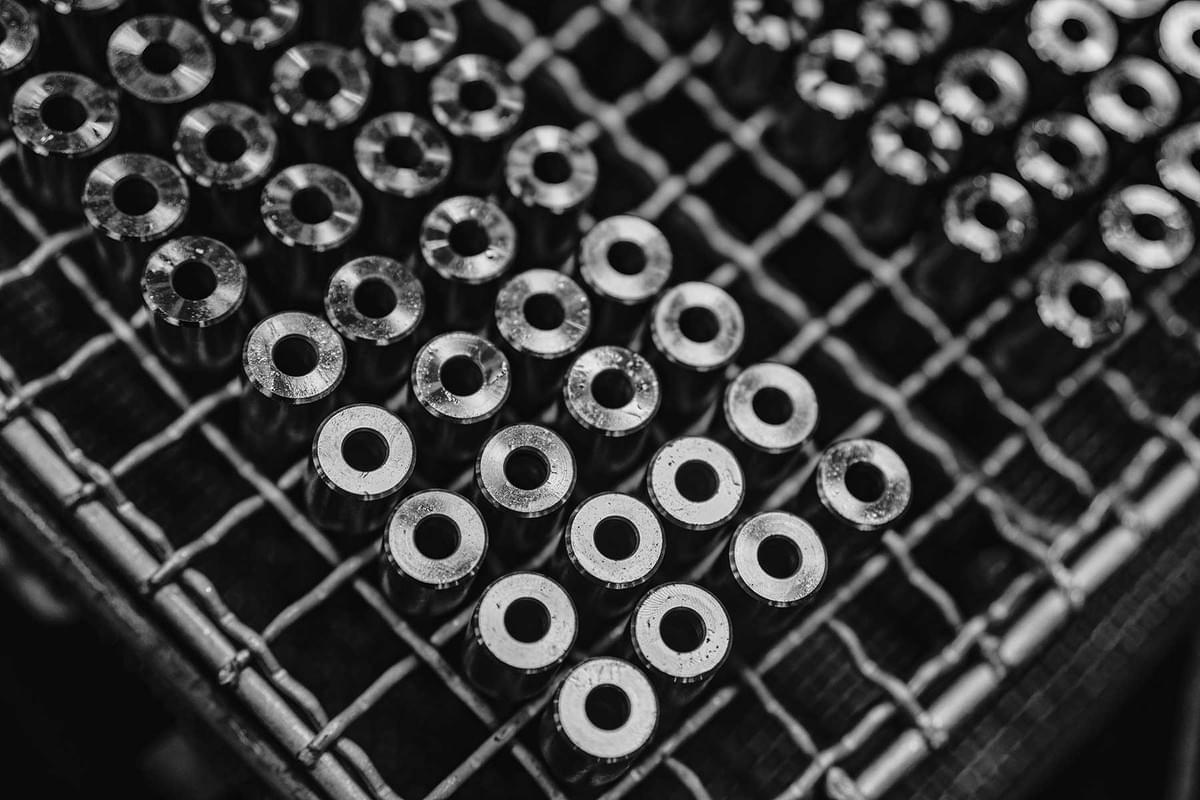

About Century Sun Metal Treating

Company History

For over 40 years, Century Sun Metal Treating has been servicing the metal working industry with high quality heat treating services. Producing the optimum metallurgical properties including excellent distortion control and uniformity of hardness have been our goal. Century Sun offers a wide range of thermal processes to assist customers throughout the world. Many OEMs and steel suppliers to the industry now specify Century Sun Metal Treating as the vendor of choice.

Quality

Detailed hardness inspections, special blasting, and protective packaging of finished parts are among the final steps taken before shipments leave our facility. We are always ready to provide the highest quality, fast and convenient service, and competitive prices.

Most Diversified Heat Treating Facility in the Industry

Century Sun offers a variety of hardening and surface treatments, so the best process can be selected for the customer’s tooling and specifications. Our operating software offers complete documentation from order entry to final delivery, in order to assist with customers' quality requirements.

Service & Reliability

Our fleet of trucks assures customers of consistent turn-around and delivery time. Located next to a full-service, commercial airport, we can easily serve customer needs around the country. Century Sun Metal Treating is serviced daily 24/7, by all major common carriers and expeditors throughout North America.

Century Sun Metal Treating Brochure